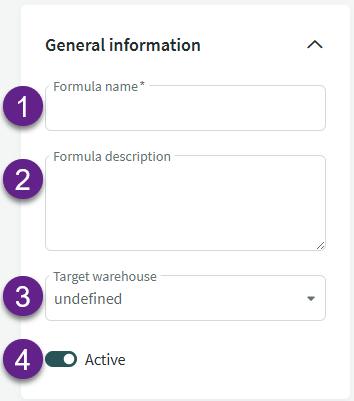

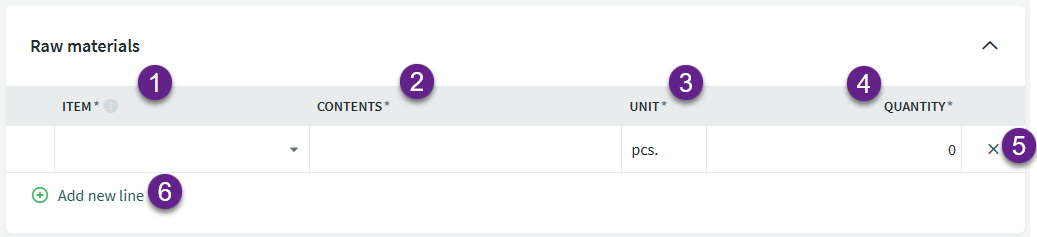

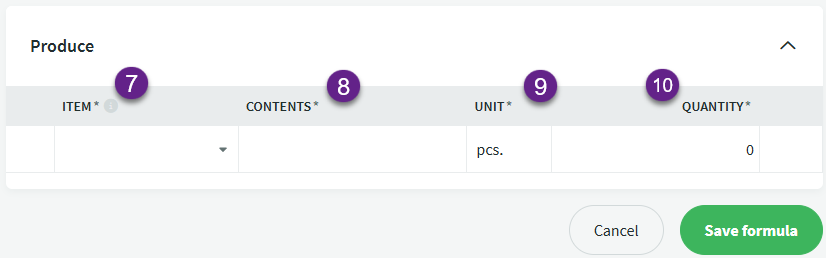

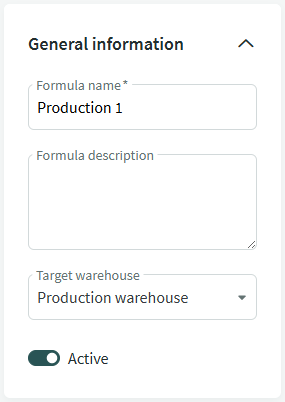

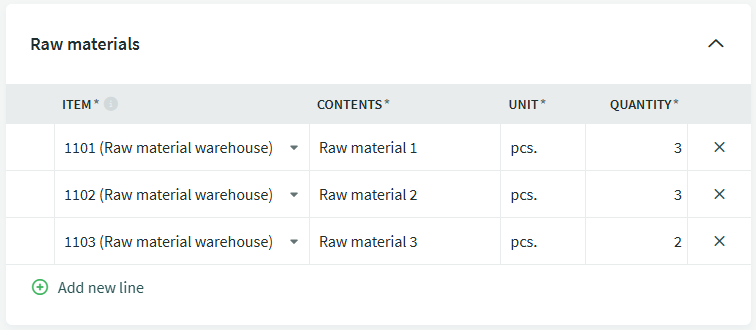

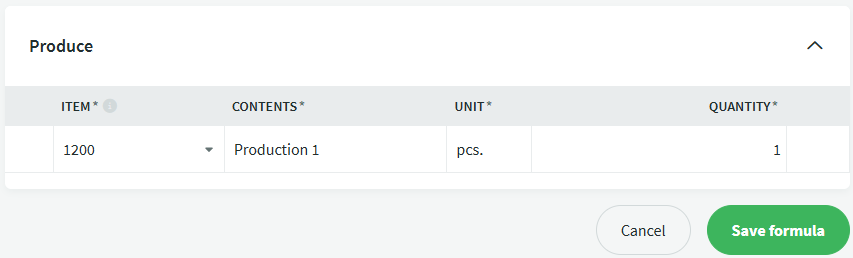

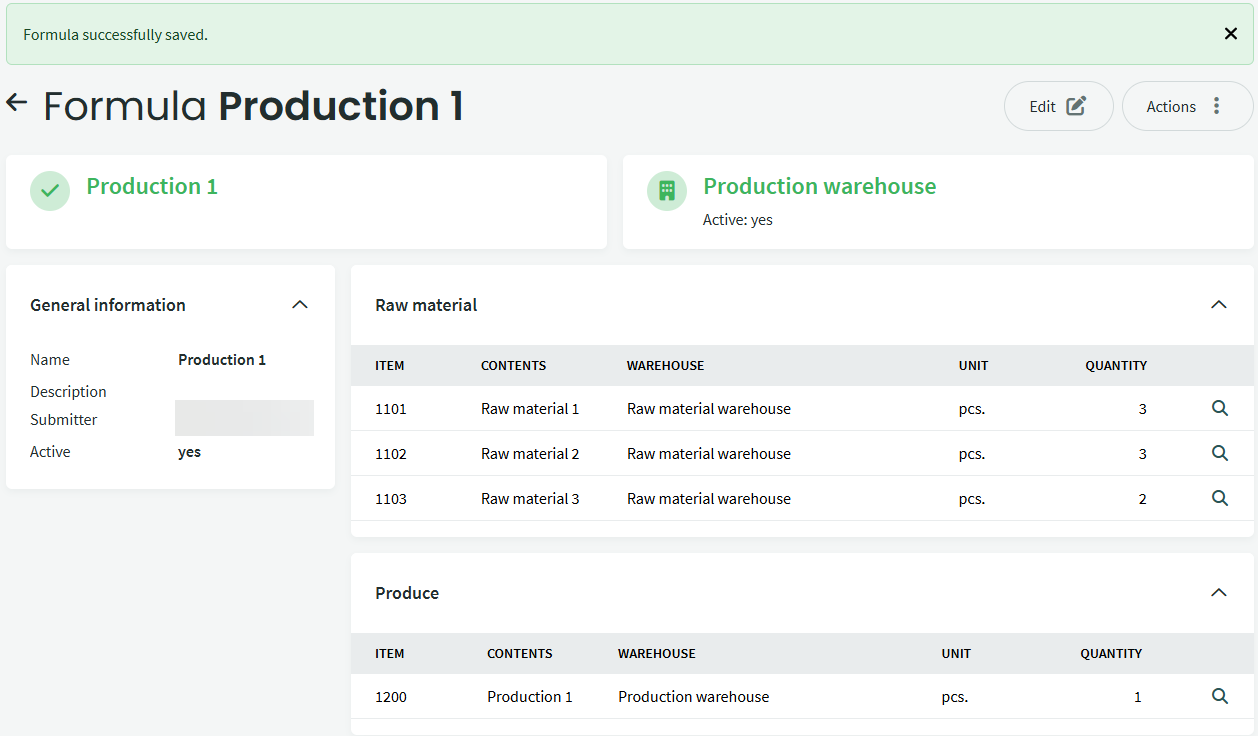

If a company is engaged in production, formulas can be used to simplify the entry of production. A formula defines the composition of a specific finished product, specifying the raw materials (components) to be used and their quantities. Each formula is linked to one specific finished product – it is not possible to include multiple different finished products in a single formula.

Warehouse -> Formulas

When adding a formula, inventory is not checked, so the products included in the formula do not need to be in stock. Inventory is checked when adding a production.

Only warehouse items can be used when entering a formula. If a required item is not available, it must first be added under Warehouse -> Items.

● We recommend creating a formula for one unit of the finished product. When entering a production, the quantity of finished product can be adjusted, and the raw material quantities will be automatically recalculated. The formula can also be modified or deleted after it has been used in production.If you have any additional questions, please write to us at support@simplbooks.ee

Leave A Comment?