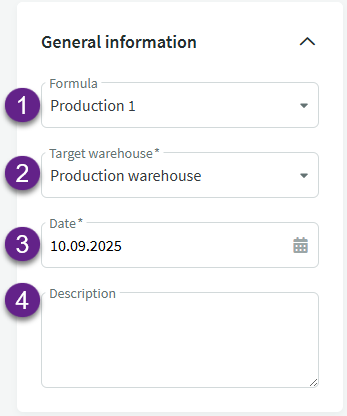

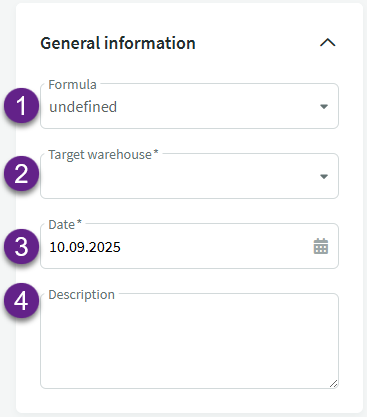

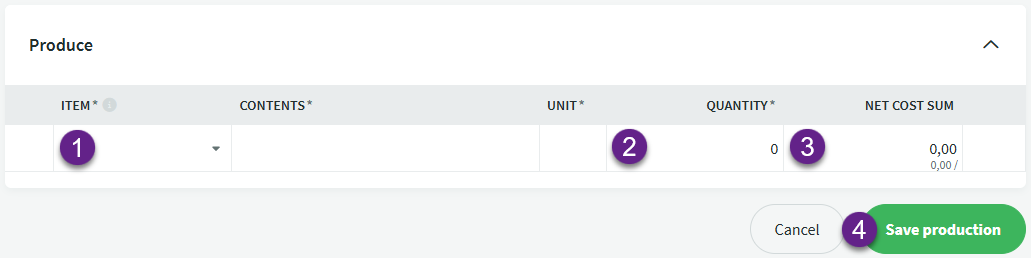

You can enter a production under Warehouse -> Production. Before doing so, ensure that the necessary items have been created (Warehouse -> Items) and that the correct warehouse is assigned (Warehouse -> Warehouses).

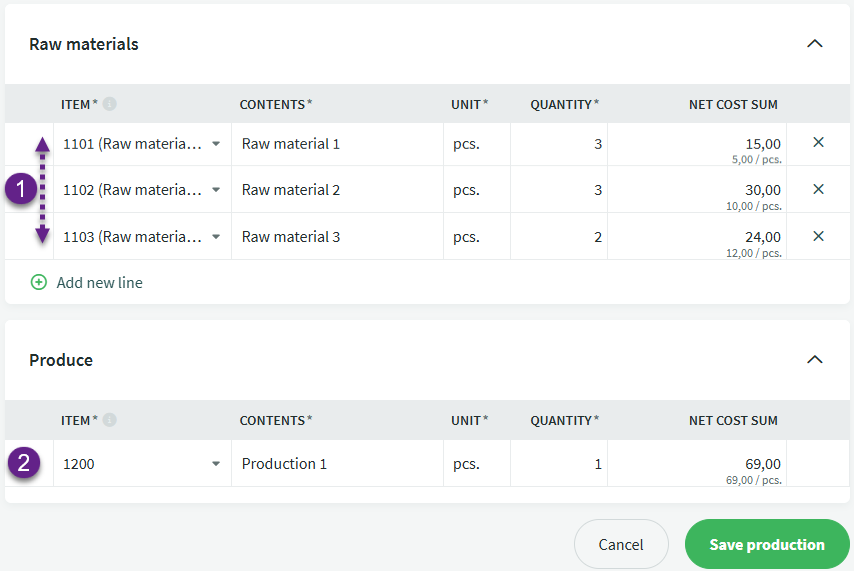

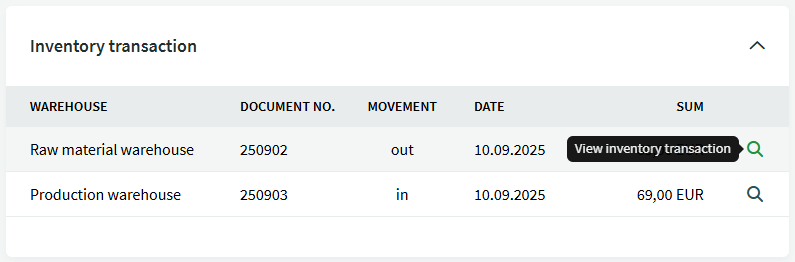

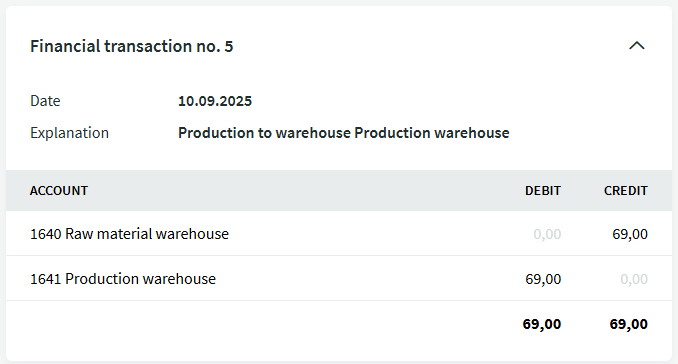

The cost of the finished product is based on the cost of the components (raw materials) used in production. After saving the production, a financial transaction is automatically created to decrease the raw materials inventory account and increase the finished goods inventory account.

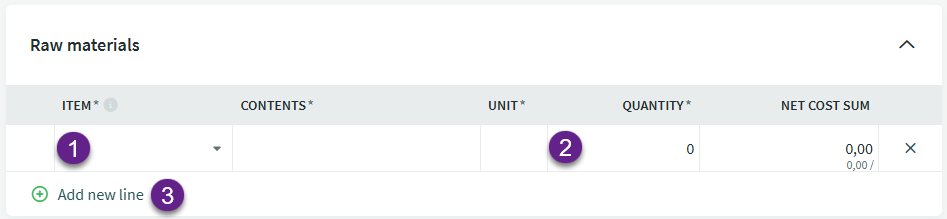

● Only warehouse items with sufficient stock can be used in production. ● Service items and additional costs (for example, labor costs) cannot be added to production.If you have any additional questions, please write to us at support@simplbooks.ee

Leave A Comment?